| Citation: | Ragiman S, Talluri K B, NRG V, B Vidya S. Unmanned aerial vehicle (UAV)-assisted pesticide application for pest and disease prevention and control in rice. Int J Agric & Biol Eng, 2024; 17(5): 88–95. DOI: 10.25165/j.ijabe.20241705.8640 |

Unmanned Aerial Vehicles (UAVs) have emerged as innovative tools in agriculture, revolutionizing crop protection practices and the use of pesticide combinations to aid the management of insect pests and diseases in a single application. This research delves into assessing the efficacy of drone-based pesticide spraying utilizing combinations of pesticides to combat insect pests and diseases in rice cultivation. In kharif 2022, the physically compatible combination of insecticides (chlorantraniliprole 18.5% SC and tetraniliprole 200 SC) with fungicides (picoxystrobin 7.5%+tricyclazole 22.5% SC and tebuconazole 50%+trifloxystrobin 25% WG) were administered via drones and compared with conventional Taiwan sprayer. The results indicated that tebuconazole+trifloxystrobin, when applied via drones, exhibited the highest control efficacy against the brown spot, sheath blight, and sheath rot (47.8%, 77.4%, and 75.2% respectively). Moreover, combination treatment, i.e., tetraniliprole+(tebuconazole+trifloxystrobin), applied using a drone, achieved the most effective control (78.1%) against grain discoloration. Additionally, drone-based tetraniliprole application showed effectiveness against stem borer and whorl maggot (efficacy rates of 49.1%, 66.6%, and 60.7% for dead hearts, white ear, and whorl maggot, respectively). Overall, the pesticide combination treatment, i.e., tetraniliprole+(tebuconazole+trifloxystrobin), showed higher control efficacy against all the insect pests and diseases and recorded the highest grain yield of 7995 kg/hm2 with an incremental cost-benefit ratio (ICBR) of (1:5.63) when sprayed with a drone. Overall, this study underscores the potential of drone-assisted pesticide application in effectively managing multiple insect pests and diseases in rice, offering superior precision, efficacy, efficiency, and yield.

Rice (Oryza sativa L.) is a vital global staple, and India ranks second in its production, encompassing approximately 45.7 million hm2 of cultivation and producing an impressive 124.36 million t per year, accounting for 22% of the total global production[1]. However, this production gain resulting from input-intensive cultivation has brought about a significant rise in the incidence of various insect pests and diseases, posing a substantial threat to rice production. Among biotic challenges being faced by the farmers, the yellow stem borer (Scirpophaga incertulas), brown planthopper (Nilaparvata lugens), blast caused by Magnaporthe oryzae, bacterial leaf blight caused by Xanthomonas oryzae pv. oryzae, and sheath blight caused by Rhizoctonia solani Kühn stand out as the major entities responsible for inflicting severe economic losses in rice. One study reports that the extent of losses in rice grain yield was 27.9% by insect pests, 15.6% by diseases, and 37% by weeds[2].

Integrated pest and disease management (IPDM) strategies offer an effective means of crop protection by utilizing a combination of methods, such as cultural practices, biological control, and judicious use of pesticides. However, farmers often heavily rely on spraying pesticides, particularly insecticides and fungicides, due to their quick action, easy availability, and perceived reliability. The simultaneous occurrence of insect pests and diseases often necessitates the application of 2-3 pesticides at a time as a pesticide tank mixture. In addition, labor shortages have prompted farmers, both knowingly and unknowingly, to the use of pesticide mixtures. However, the utilization of pesticide combinations or mixtures poses several challenges. In some cases, physical incompatibility between the components of the mixture may lead to phytotoxicity or reduced efficacy, while in certain instances, it may even contribute to pesticide resistance development[3].

Over the last few decades, pesticide application in agriculture has traditionally been carried out through ground and aerial spraying methods. Developed countries like the USA and those of Europe have witnessed the development of various ground application equipment to meet diverse spray requirements[4]. However, knapsack sprayers commonly employed in ground spraying are associated with increased pesticide exposure for the operator, apart from ineffective chemical application[5]. According to the World Health Organization (WHO), an estimated 1 million humans annually are affected by acute poisoning through contact with pesticides. Alarmingly, the annual death rate attributed to pesticide poisoning ranges from 0.4% to 1.9%[6]. Taking cognizance of the problems associated with ground spraying using different kinds of equipment, there is an urgent need for safer and more efficient methods of pesticide application in crop protection.

In contrast, aerial application systems, particularly through the use of unmanned aerial vehicles (UAVs) or drones, offer a promising alternative as they offer precise and efficient application of pesticides, reducing wastage and achieving faster application, saving time and labor costs alongside offering greater potential in minimizing the operator exposure to highly toxic pesticides. Agricultural aerial spraying by drones is often the most economical and rapid method for providing efficient and effective applications for crop pest control, allowing for quick response time during sudden pest outbreaks[7].

UAVs have emerged as innovative tools in agriculture, revolutionizing crop protection practices. With the ability to be operated remotely or autonomously, UAV spraying has become an alternative plant protection equipment with increased safety, improved maneuverability, and enhanced efficiency in comparison to traditional ground spraying methods. These attributes, along with the timely coverage of larger areas and the ability to navigate complex terrains, make UAVs highly advantageous for pesticide application. The global drone market has witnessed significant growth, and according to market intelligence and advisory from Bureau of Indian Standards (BIS) research, it is estimated to reach a staggering 28.47billion(approximatelyRs.2.09lakhcrores)bytheendof2023.Notably,thedominanceoftheUnitedStates,China,andIsraelinthedronemarkethasbeenprominent.India,however,isprojectedtocontributearound4.251.81 billion (Rs. 13 330 crores) by the end of the financial year (FY) 2026, with a compound annual growth rate (CAGR) of 14.61%[8].

Recognizing the immense potential of drone-based technologies in agriculture, the Government of India has taken proactive steps to facilitate the adoption of this groundbreaking technology in the agricultural sector by introducing pro-drone policies. In addition, the Ministry of Civil Aviation announced the updated Drone Rules of 2021, replacing the highly criticized UAS rules released in March 2021. The liberalized Drone Rules of 2021 are more permissive and are expected to remove all unnecessary operational and entry barriers and create a strong drone ecosystem in the country to make India a global hub for drones by 2030. The government’s focus on bringing drone-based technologies into agriculture highlights the importance of embracing this innovation as a necessary tool for the future of precision agriculture. While addressing the nation in the historic Red Fort on the occasion of the 77th Anniversary of Independence, Prime Minister Narendra Modi announced the “Drone ki Udaan” initiative, a compelling scheme in which

The present study aimed to assess the viability of utilizing UAVs for the aerial application of physically compatible pesticide combinations to combat insect pests and diseases in rice cultivation. Building upon physical compatibility assessments, two insecticides (chlorantraniliprole 18.5% SC and tetraniliprole 200 SC) and two fungicides (picoxystrobin 7.5%+tricyclazole 22.5% SC and tebuconazole 50%+trifloxystrobin 25% WG) were selected to conduct a comprehensive investigation of their compatibility, bio-efficacy, and phytotoxicity in the field conditions. This investigation adopted an innovative drone-based pesticide application, which was compared with manual spraying using a Taiwan sprayer. The selection of these particular pesticides was made based on different factors, including the outcomes of the physical compatibility tests, observations of prevalent pests during the pre-count phase, cost-effectiveness of the pesticides, and their market availability.

The present investigation was carried out at the Institute of Rice Research, Agricultural Research Institute, Rajendranagar, Hyderabad (50°18′N, 53°77′E), which is situated at an altitude of 542.6 m above the MSL during kharif (Vanakalam), 2022. According to Troll’s classification, it comes under semi-arid tropics (SAT) and is located in the Southern Telangana agro-climatic zone of the Telangana state.

The variety of rice is Samba Mahsuri (BPT 5204). The net area of each plot per treatment/replication is 360 m2, and the total plot area per treatment is 1650 m2.

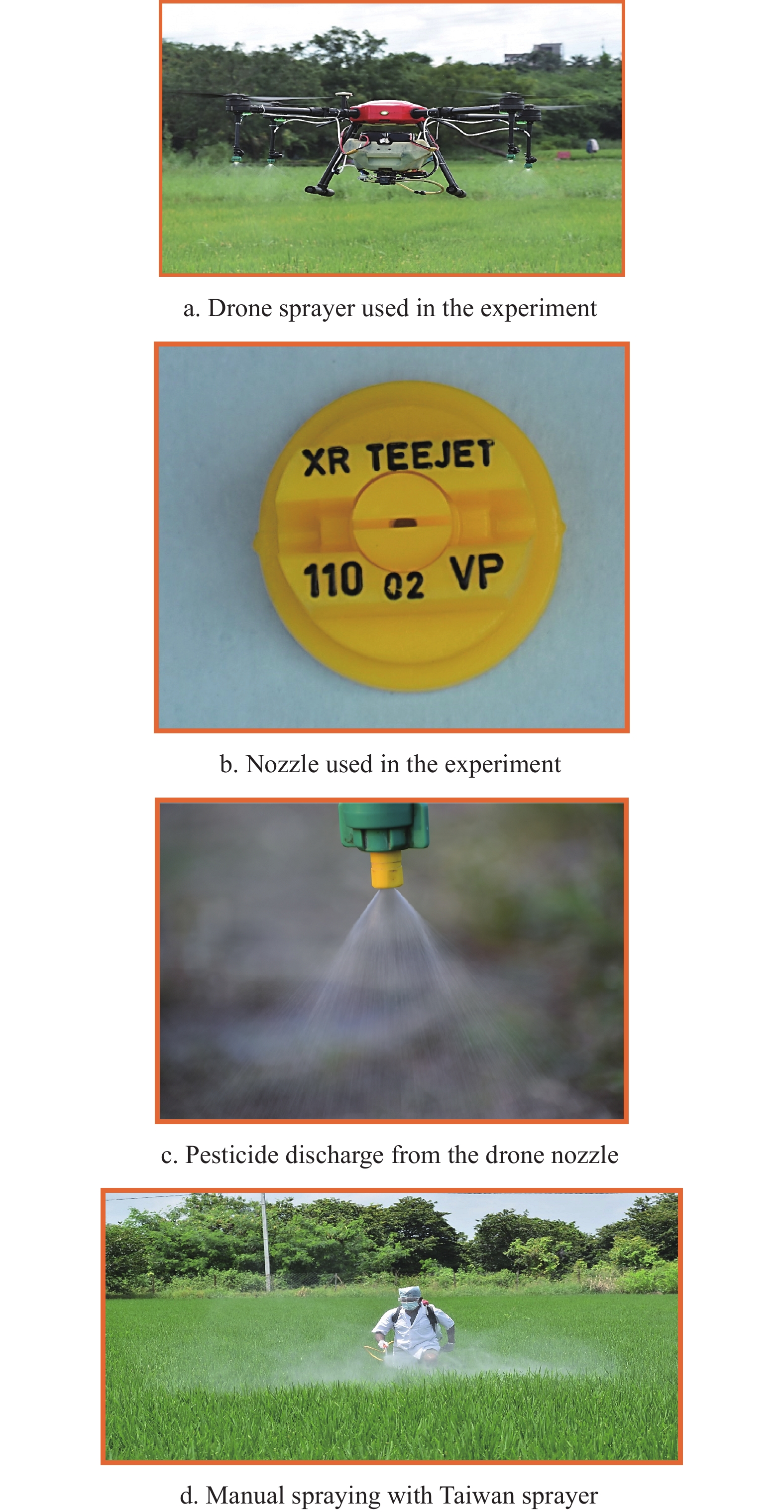

As shown in Figure 1a, the model of UAV (drone) used in this aerial spraying was battery motive AGRICOPTER AG 365 (Marut Dronetech Pvt. Ltd., Hyderabad, India), and the detailed specifications are presented in Table 1. The accuracy of the flight height and flight velocity was controlled by ground radar and a well-trained drone pilot. The nozzle tip used for the drone sprayer was XR

| Particulars | Parameter |

| Model | AGRICOPTER AG 365 with UIN UA00132S1EX |

| Service provider | Marut Dronetech Pvt. Ltd., Hyderabad |

| Dimensions | 1920 mm×1820 mm×500 mm |

| Pay load capacity/volume | 10 L |

| Endurance | 20 min |

| Power battery | 2 Nos. of |

| Number of nozzles | 4 Nos. |

| Nozzle type | XR 11002VP (Extended range-Flat fan) |

| Spray angle of the nozzle and tip | 110° |

| Spray pressure | 1.40-2.06 bars |

| Pump pressure | 1 MPa |

| Flight mode options | Manual/Semi-autonomous/Fully autonomous |

| Fail safe features | Return to home, hovering on signal lost |

| Spraying width | 3-5 m |

| Max. flying speed | 5.0 m/s |

| Max. flow velocity | 200-800 mL/min |

At the maximum tillering stage, the incidence of stem borer (dead hearts), whorl maggot, and brown spot was observed in the field at 66 d after transplanting (DAT). Based on this observation, after attaining the economic threshold level (ETL), the first application of treatments (Table 2) was done at 67 DAT after collecting the pre-count data of the observed insect pests and diseases. The phytotoxicity observations were recorded at 1, 3, 5, 10, 15, and 20 d after the first spray. The second spray was taken up at 100 DAT after collecting the pre-count data of sheath blight, sheath rot, and stem borer (white ears). Phytotoxicity observations were once again recorded at similar intervals. At the time of the first spray, the initial GPS mapping of treatments and replications for autonomous drone spraying was done and the same maps were then utilized for the second application, ensuring consistency in treatment application within the field. To prevent the potential issue of drift and contamination between the treatments, a buffer zone of 5 m was maintained between adjacent treatments/replication. Each replication consisted of a minimum plot size of 360 m² to ensure adequate coverage during the drone-based pesticide application in rice. Consistency and standardization were maintained across all the treatments by following the recommended flight parameters outlined in Table 3. The crop-specific standard operating procedures (SOPs) for the application of pesticides with a drone were released by the Ministry of Agriculture and Farmers Welfare, government of India, and SOPs for drone-based pesticide application in rice developed by Varma et al.[11] were followed in the present investigation. While operating the drones in the field for experimenting, the weather conditions such as wind speed were measured using an Anemometer (Lutron, AM 4201, Taiwan), while a hand-held hygrometer (HTC, 288 CTH, China) was used to record temperature and relative humidity.

| Trt. No. | Treatment particulars | Spraying equipment |

| T1 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L | Drone |

| T2 | Tetraniliprole 200 SC @ 6.25 mL/L | Drone |

| T3 | Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L | Drone |

| T4 | Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | Drone |

| T5 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 25 mL/L | Drone |

| T6 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 5 g/L | Drone |

| T7 | Tetraniliprole 200 SC @ 6.25 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 25 mL/L | Drone |

| T8 | Tetraniliprole 200 SC @ 6.25 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 5 g/L | Drone |

| T9 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 2.66 mL/L | Taiwan sprayer |

| T10 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 0.53 g/L | Taiwan sprayer |

| T11 | Tetraniliprole 200 SC @ 0.6 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 2.66 mL/L | Taiwan sprayer |

| T12 | Tetraniliprole 200 SC @ 0.6 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 0.53 g/L | Taiwan sprayer |

| T13 | Untreated Control | -- |

| Note: SC: Suspension Concentrate; WG: Wettable Granules. | ||

| Drone spray parameters | SOPs followed |

| Flight height | 2.5 m above the crop canopy |

| Flight speed | 3.6 m/s |

| Nozzle type | XR |

| Number of nozzles | 4 |

| Spray width | 3.5 m |

| Spray volume | 40 L/hm |

| Wind speed for drone fly | <5.0 m/s |

Within each replication, a random selection of 10 plants was made within the valid observation zone, as illustrated in Figure 2. Observations on stem borer incidence were recorded from 10 randomly selected hills/replications at the maximum tillering stage (dead hearts, Figure 3b) and at the reproductive stage (white ears, Figure 4c) before and after the application of pesticide mixtures and at 7 and 14 days after spraying (DAS). The percentage of dead hearts and white ears were calculated according to Equations (1) and (2)[12].

| Dead hearts = No. of dead heartsTotal No. of tillers×100{\text%} | (1) |

| White ear = No. of white earsTotal No. of panicle bearing tillers×100% | (2) |

Observations on whorl maggot incidence (Figure 3c) were recorded from 10 randomly selected hills/replications at vegetative stage during first spraying before and after the application of pesticide mixtures and at 7 and 14 DAS. The percentage of whorl maggot incidence was calculated according to Equation (3).

| Whorl maggot incidence = No. of whorl maggot damaged leavesTotal No. of leaves×100{\text%} | (3) |

Brown spot disease incidence (Figure 3a) was recorded from 10 randomly selected hills/replications during first spray, before and after the application of pesticide mixtures at 7 and 14 DAS.

| Brown spot incidence = No. of infected leavesTotal No. of leaves×100\% | (4) |

Observations on sheath blight disease severity (Figure 4a) were recorded from 10 randomly selected hills/replications during first spraying before and after the application of pesticide mixtures at 7 and 14 DAS and percent disease index was computed using the scale (Table 4) given by the standard evaluation system for rice[13].

| Scale | Relative lesion height (RLH) |

| 0 | No infection observed |

| 1 | Lesions limited to lower 20% of the plant height |

| 3 | 20%-30% |

| 5 | 31%-45% |

| 7 | 46%-65% |

| 9 | More than 65% |

The percent disease index (PDI) was calculated according to Equation (5).

| PDI = Sum of disease ratingsNo. of plants observed×Maximum disease rating×100{\text%} | (5) |

Observations on sheath rot disease incidence (Figure 4b) were recorded from 10 randomly selected hills/replications, before and after the application of pesticide mixtures at 7 and 14 DAS.

| Sheath rot incidence = No. of sheath rot infected tillersTotal No. of panicle bearing tillers×100{\text%} | (6) |

Incidence of grain discoloration was estimated by counting grains with more than 25% affected glume surface from the sample of 100 seeds collected per each replication in the treatments at the time of harvest. The percent grain discoloration was calculated according to Equation (7).

| Grain discoloration = No. of discoloured grainsTotal No. of grains in collected sample×100{\text%} | (7) |

The mean percent efficacy of pesticide combinations over control for brown spot, sheath blight, sheath rot, grain discoloration, stem borer, and whorl maggot were computed using Equation (8).

| Control efficacy = C−TC×100% | (8) |

where, C is the percent incidence in control; T is the percent incidence in treatment.

Observations on phytotoxicity were taken at 1, 3, 5, 10, 15, and 20 DAS with a 0-10 rating scale[14]. The observations were recorded individually for yellowing, stunting, chlorosis, necrosis, wilting, scorching, vein clearing, epinasty and hyponasty, etc., as per the phytotoxicity rating scale. The percent injury was calculated by Equation (9):

| Percent injury = Total grade pointsMaxgrade×No. of leaves observed×100{\text%} | (9) |

In the bio-efficacy field experiment, observations were taken to examine the efficiency of drone spraying over the traditional Taiwan sprayer, considering factors such as time and water saving, as well as yield improvement in pesticide application[15]. The study aimed to evaluate the effectiveness of drone spraying technology by comparing it with the conventional Taiwan sprayer.

The experimental data on various characteristics recorded throughout the course of investigation were statistically analyzed in randomized complete block design as per Gomez and Gomez[16]. Significant differences between treatments were calculated using analysis of variance (ANOVA) and Duncan’s test (DMRT) at a significance level of 95% with the OPSTAT software package (Chaudhary Charan Singh, Haryana Agricultural University, Hisar, Haryana, India)[17]. Wherever statistical significance was observed, the critical difference (CD) at 0.05 level of probability was worked out for comparison. Non-significant comparison was indicated as NS.

In the bio-efficacy evaluation during the kharif 2022, the selected insecticides (chlorantraniliprole 18.5% SC and tetraniliprole 200 SC) along with selected fungicides (picoxystrobin 7.5%+tricyclazole 22.5% SC and tebuconazole 50%+trifloxystrobin 25% WG) were sprayed using a drone (UAV) and compared with a Taiwan sprayer in rice fields for their effectiveness against brown spot, yellow stem borer (dead hearts), and whorl maggot of rice during the first spray, and sheath blight, sheath rot, grain discoloration, and yellow stem borer (white ears) during the second spray. This study marks the first of its kind in evaluation of the efficacy of pesticides applied using drone technology in rice cultivation.

In this study, the variations in pests and disease incidence at 14 DAS are represented in Table 5. The control efficacy of insecticide and fungicide combinations applied using UAV and Taiwan sprayer against insect pests of rice (Figure 5) and against diseases (Figure 6) revealed that, for the first spray among the treatments tested, the treatment T4 (tebuconazole + trifloxystrobin) recorded the highest control efficacy against brown spot (47.8%), followed by T10, i.e., chlorantraniliprole + (tebuconazole + trifloxystrobin), with 44.7%. The treatment T2 (tetraniliprole) recorded the highest control efficacy against dead hearts (49.1%), followed by T8, i.e., tetraniliprole + (tebuconazole + trifloxystrobin), with 43.1%. Lastly, for whorl maggot, the treatments with the best control efficacy were T2 (tetraniliprole) with 60.7%, followed by T12, i.e., tetraniliprole + (tebuconazole + trifloxystrobin), with 52.5%. During the second spray, the best control efficacy against sheath blight (77.4%) was found with T4 (tebuconazole + trifloxystrobin), followed by T5, i.e., chlorantraniliprole + (picoxystrobin + tricyclazole), with 74.1%, and both were applied using a drone. Promising control efficacy against sheath rot was found with T4 (tebuconazole + trifloxystrobin, 75.2%), followed by T3, i.e., (picoxystrobin + tricyclazole, 72.1 %), which was applied with a drone. Regarding grain discoloration, the maximum control efficacy (78.1%) was found with T8, i.e., tetraniliprole + (tebuconazole + trifloxystrobin), followed by T4 (tebuconazole + trifloxystrobin) with 71.9%, and both were applied with drone. The best control efficacy for white ears was found with T2 (tetraniliprole) with 66.6%, followed by the combination treatment applied using Taiwan sprayer, T12, i.e., tetraniliprole + (tebuconazole + trifloxystrobin), with 60.0%. None of the treatments induced any phytotoxicity symptoms such as yellowing, leaf tip drying, or vein clearing at any of the observed time points (1 DAS, 3 DAS, 5 DAS, 10 DAS, 15 DAS, and 20 DAS) after the first and second spray. This suggests that the selected pesticides alone and their combination treatments were safe and well-tolerated by rice plants at Taiwan and drone spraying concentrations. Hence, these combinations will be recommended to the farming community for safe use in rice. Further, drones as additional spraying equipment without changing the recommended dose of pesticide followed for ground spraying for the benefit of the farming community.

| Trt. No. |

Treatment details | YSB | WM/% | BS/% | SHB (PDI)/% | SHR/% | GD/% | Grain yield/ kg∙hm–2 |

|

| DH/% | WE/% | ||||||||

| T1 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L | 6.45ab(14.65)* | 6.85a(15.04) | 7.23ab(15.54) | 9.22c(17.47) | 51.85cd(46.04) | 18.44c(25.40) | 17.00c(26.49) | 5451hi |

| T2 | Tetraniliprole 200 SC @ 6.25 mL/L | 4.23a(11.83) | 5.94a(14.02) | 5.67a(13.70) | 7.19bc(15.52) | 48.52c(44.13) | 19.61c(26.23) | 18.00c(25.51) | 5614hi |

| T3 | Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L |

9.46d(17.69) | 15.21b(22.80) | 13.10d(21.20) | 3.09a(10.08) | 20.37ab(26.45) | 6.35ab(14.44) | 10.33ab(17.34) | 6024gh |

| T4 | Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L |

11.33d(19.64) | 17.09b(24.83) | 14.03d(21.92) | 2.62a(9.30) | 12.96a(20.60) | 4.44a(12.11) | 7.00a(14.04) | 6275gh |

| T5 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L |

8.36bc(16.78) | 8.97a(17.38) | 11.44bc(19.70) | 3.59a(10.91) | 12.96a(20.60) | 7.26ab(15.38) | 9.00b(18.71) | 6900de |

| T6 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L |

8.82bc(17.25) | 8.68a(17.10) | 10.38bc(18.71) | 3.28a(10.43) | 17.78ab(23.99) | 5.76ab(13.83) | 7.67ab(15.97) | 7726b |

| T7 | Tetraniliprole 200 SC @ 6.25 mL∙L–1+Picoxystrobin 7.5%+Tricyclazole 22.5% SC@ 25 mL/L |

6.90abc(15.20) | 7.69a(16.08) | 6.91ab(15.06) | 3.63a(10.97) | 25.93ab(30.56) | 7.38ab(15.66) | 9.33ab(17.68) | 7459bc |

| T8 | Tetraniliprole 200 SC @ 6.25 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L |

6.21abc(14.37) | 7.68a(16.06) | 7.08ab(15.35) | 3.44a(10.65) | 16.67ab(23.88) | 5.69ab(13.78) | 6.33a(14.04) | 7995a |

| T9 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L |

5.60ab(13.65) | 7.85a(16.15) | 8.98bc(17.42) | 3.70a(11.07) | 14.81a(22.34) | 8.41b(16.82) | 9.67ab(17.97) | 6729ef |

| T10 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L |

7.97ab(16.38) | 8.77a(17.21) | 8.49bc(16.91) | 3.21a(10.32) | 15.93a(23.36) | 5.79ab(13.90) | 8.33ab(16.07) | 7379bcd |

| T11 | Tetraniliprole 200 SC @ 0.6 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L | 7.90bc(16.12) | 7.00a(15.26) | 9.03bc(17.40) | 3.22a(10.31) | 20.37ab(26.77) | 6.84ab(14.99) | 10.67b(18.37) | 7155cde |

| T12 | Tetraniliprole 200 SC @ 0.6 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L |

6.96abc(15.25) | 5.86a(13.93) | 6.82ab(15.11) | 3.28a(10.42) | 18.52ab(25.42) | 5.08ab (12.97) | 9.00ab(17.07) | 8098a |

| T13 | Untreated control | 11.45d(19.76) | 18.07b(25.12) | 17.17e(24.45) | 10.93c(14.08) | 57.78d(49.45) | 27.16d(31.39) | 27.33d(31.49) | 4809j |

| Standard error (SE/m±) | 1.00 | 1.08 | 0.97 | 0.68 | 2.93 | 1.07 | 1.42 | 172.65 | |

| Critical difference CD (at 5% significance level) | 2.94 | 3.19 | 2.86 | 2.01 | 8.62 | 3.16 | 4.19 | 506.94 | |

| Coefficient of variation (CV/%) | 10.81 | 10.62 | 9.45 | 10.12 | 17.24 | 10.68 | 12.82 | 4.34 | |

| Note: YSB: Yellow stem borer; DH: Dead hearts; WE: White ears; WM: Whorl maggot; BS: Brown spot; SHB: Sheath blight; PDI: Percent disease index; SHR: Sheath rot; GD: Grain discoloration. *Figures in parentheses are angular transformed values. Numerical superscript letters represent Duncan’s multiple range test analysis. Figures in bold represent best-performing treatments. | |||||||||

The results of the present study are in line with Wang et al.[18], who revealed that when chlorantraniliprole 18.5% SC was applied using a drone against rice stem borer, significantly higher control efficacy (more than 90% compared to untreated control) was achieved at flight height of 2-4 m and flight velocity of 3-4 m/s. These results support the current study’s findings of the higher efficacy observed with chlorantraniliprole against stem borer (dead hearts). Effective pest control practices depend on proper application practices that deliver a quality spray. The better control efficacy achieved in drone spraying treatments compared to Taiwan sprayer treatments might be due to the higher droplet coverage and deposition in drone spraying treatments due to their fine droplets. Variables including pest species, location on the plant, spray system configuration, and environmental conditions all may have a significant effect on UAV application deposition and pest control efficacy[19]. Past research has proven the feasibility of low-volume spraying via UAVs in agrichemical applications to control pests and diseases[20,21].

The treatments T12 (tetraniliprole + tebuconazole + trifloxystrobin) applied with a Taiwan sprayer and T8 (tetraniliprole + tebuconazole + trifloxystrobin) applied with a drone exhibited the highest grain yields of 8098 and 7995 kg/hm2. The untreated control had the lowest grain yield (4809 kg/hm2), confirming the importance of effective pest and disease management strategies in rice. The combination treatments sprayed via drones and Taiwan sprayer exhibited higher grain yield compared to individual pesticide application treatments irrespective of spraying equipment. The combination treatments sprayed via drone showed superior performance in terms of grain yield compared to Taiwan sprayer. These findings highlight the potential benefits of drones for pesticide application and enhanced productivity. Additionally, the study analyzed the incremental cost-benefit ratio to determine the economic feasibility of each treatment (Table 6). Among treatments tested, the highest cost-benefit ratio (1:5.88) was achieved with treatment T12, i.e., tetraniliprole + (tebuconazole + trifloxystrobin), followed by T8, i.e., tetraniliprole + (tebuconazole + trifloxystrobin) and T6, i.e., chlorantraniliprole + (tebuconazole + trifloxystrobin), which exhibited 1:5.63 and 1:5.62 ICBR, respectively. The combination treatments sprayed via drones showed higher ICBRs compared to Taiwan sprayer treatments except T12 (1:5.88), which exhibited the highest ICBR among all the pesticides tested in the present study. These findings highlight the potential benefits of using pesticide combinations and drone spraying technology to enhance rice crop productivity.

| Trt. No. | Treatment details | Grain yield/ kg∙hm-2 | Incremental yield over control/ kg∙hm-2 | Incremental returns over control/ INR∙hm-2 | Incremental cost of cultivation/ INR∙hm-2 | ICBR |

| T1 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L | 5451 | 642 | 5475 | 1: 2.39 | |

| T2 | Tetraniliprole 200 SC @ 6.25 mL/L | 5614 | 805 | 6420 | 1: 2.56 | |

| T3 | Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L | 6024 | 1215 | 5520 | 1: 4.49 | |

| T4 | Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | 6375 | 1566 | 6120 | 1: 5.22 | |

| T5 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L | 6900 | 2091 | 9995 | 1: 4.27 | |

| T6 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | 7726 | 2917 | 1: 5.62 | ||

| T7 | Tetraniliprole 200 SC @ 6.25 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC@ 25 mL/L | 7459 | 2650 | 1: 4.94 | ||

| T8 | Tetraniliprole 200 SC @ 6.25 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | 7995 | 3186 | 1: 5.63 | ||

| T9 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L | 6729 | 1920 | 9870 | 1: 3.97 | |

| T10 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L | 7379 | 2570 | 1: 5.01 | ||

| T11 | Tetraniliprole 200 SC @ 0.6 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L | 7155 | 2346 | 1: 4.43 | ||

| T12 | Tetraniliprole 200 SC @ 0.6 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L | 8098 | 3289 | 1: 5.88 | ||

| T13 | Untreated Control | 4809 | 0.00 | 0.00 | 0.00 | 0.00 |

| Note: Market price of paddy=20,400 INR/t, Cost of Chlorantraniliprole 18.5% SC (60 mL)=2237.5 INR/hm2, Tetraniliprole 200 SC (100 mL)=2710 INR/hm2, Picoxystrobin 7.5%+Tricyclazole 22.5% SC (400 mL)=2260 INR/hm2, Tebuconazole 50%+Trifloxystrobin 25% (80 g)=2560 INR/hm2 Spraying cost (hm2); Taiwan sprayer spraying charges =INR.875/- & Drone spraying charges =INR.1000/-. | ||||||

There were significant efficiency improvements associated with drone spraying over manual spraying (Table 7). The drone spraying method resulted in a water saving of 89.3%, indicating a substantial reduction in water usage compared to manual spraying. Furthermore, drone spraying demonstrated a time saving of 73.3% compared to manual spraying. Time saving can be attributed to taking timely control measures; if a large-scale disease epidemic occurs in a particular area and crop, we can cover large areas within a short period to avoid yield losses. In terms of yield improvement, drone spraying showed a range of 2.48% to 4.36% increase compared to Taiwan sprayer treatments. This positive impact on yield can be attributed to several factors, including accurate and targeted pesticide application, uniform coverage, reduced drift, and minimized human error. The higher field capacity associated with drone spraying (8 hm2/d or 20 acres/d) compared to the Taiwan sprayer (2 hm2/d or 5 acres/d) highlights the operational efficiency of drones. Similarly, the higher labor productivity achieved through drone spraying (4 hm2/labor day) compared to Taiwan sprayer (1 hm2/labor day) emphasizes the potential use of labor utilization.

| Particulars | Efficiency indices/% |

| Water saving by drone spray over Taiwan spray | 89.33% |

| Time saving by drone spray over Taiwan spray | 73.33% |

| Yield improvement by drone spray over Taiwan spray | 2.48%-4.36% |

| Field capacity • Drone spray • Taiwan spray | 8 hm2/d (20 acres/d) 2 hm2/d (5 acres/d) |

| Labor productivity • Drone spray • Taiwan spray | 4 hm2/d (10 acres/labor day) 1 hm2/d (2.5 acres/labor day) |

The findings highlight the potential of drone spraying as a valuable tool in modern crop protection strategies, offering numerous benefits to farmers, the environment, and overall agricultural productivity by following the crop-specific SOPs for the safe use of pesticides using drones (UAVs) in crops given by the Ministry of Agriculture & Farmers Welfare, government of India. The drone spraying method resulted in a water saving of 89.3% and time saving of 73.3% compared to manual spraying. In terms of yield improvement, drone spraying showed a range of 2.48% to 4.36% increase compared to ground manual sprayers. With all the advantages driven by drone spraying, it also has some disadvantages including spray drift, vulnerability to adverse weather conditions like strong winds and rain, and limited flight time due to battery endurance. These can be addressed by future research on improvising drone technology. Overall, the present study supports the safety and effectiveness of the selected treatments in rice and highlights the potential advantage of using drone technology for pesticide spraying, both in terms of crop health and economic returns.

Successful implementation of drone technology can be achieved by assessing cost economics, adoption rates, and economic viability for successful integration of drone-based spraying among farmers and the establishment of custom hiring centers (CHCs) or hi-tech hubs. To achieve effective pest and disease management, integration of drone-embedded AI algorithms for detecting, diagnosing, and monitoring rice insect pests and diseases is crucial for timely and optimized pesticide applications. Investigating factors influencing pesticide drift and implementing strategies to minimize off-target effects during drone spraying, alongside designing spray formulations optimized for drone-based applications such as reducing foaming and ensuring physical compatibility, will lead to more efficient pest control.

The authors are highly thankful to the authorities of Professor Jayashankar Telangana State Agricultural University, Hyderabad, India, Institute of Rice Research (IRR), Hyderabad, India and Seed Research & Technology Centre, Hyderabad, India for providing necessary infrastructural facilities and financial support to conduct this research work.

| [1] |

INDIASTAT. Rice production and productivity. 2021. Available: https://www.indiastat.com/Home/DataSearch?Keyword=Rice%20Production. Accessed on [2022-08-22].

|

| [2] |

Mondal D, Ghosh A, Roy D, Kumar A, Shamurailatpam D, Bera S, et al. Yield loss assessment of rice (Oryza sativa L.) due to different biotic stresses under system of rice intensification (SRI). Journal of Entomology and Zoology Studies, 2017; 5(4): 1974–1980.

|

| [3] |

Peshney N L. Compatibility of fungicides with some insecticides with reference to fungitoxicity and phytotoxicity.Punjabrao Krishi Vidyapeeth Research Journal, 1990; 14: 35–37.

|

| [4] |

Faical B S, Freitas H, Gomes P H, Mano L Y, Pessin G, de Carvalho A C P L F, et al. An adaptive approach for UAV-based pesticide spraying in dynamic environments. Computers and Electronics in Agriculture, 2017; 138: 210–223. doi: 10.1016/j.compag.2017.04.011

|

| [5] |

Tudi M, Daniel Ruan H, Wang L, Lyu J, Sadler R, Connell D, et al. Agriculture development, pesticide application and its impact on the environment. International Journal of Environmental Research and Public Health, 2021; 18(3): 1112. doi: 10.3390/ijerph18031112

|

| [6] |

Report 2021, Joint FAO/WHO meeting on pesticide residues. 2021; Available: https://openknowledge.fao.org/server/api/core/bitstreams/fad4f84a-d748-4d2a-bbef-1db01ac371dd/content. Accessed on [2022-10-05].

|

| [7] |

Chen C C, Li S G, Wu X Y, Wang Y X, Kang F. Analysis of droplet size uniformity and selection of spray parameters based on the biological optimum particle size theory. Environmental Research, 2022; 204: 112076. doi: 10.1016/j.envres.2021.112076

|

| [8] |

GOI. Crop specific standard operating procedure (SOP) for the application of pesticides with drones. 2021. Available: https://farmech.dac.gov.in/New_Folder/TTC_SOP_2023-4.pdf. Accessed on [2022-07-05].

|

| [9] |

Anonymous, ET Government, Drone Ki Udaan. 2023; Available: https://government.economictimes.indiatimes.com/news/defence/drone-ki-udaan-will-train-15000-womens-self-help-groups-to-operate-drones-says-pm-modi/102743652. Accessed on [2023-08-15].

|

| [10] |

Anonymous, ANI News service, To fast track agri-drone adaptation. 2022; https://theprint.in/india/to-fast-track-agri-drone-adoption-centre-approves-477-pesticides-for-drone-usage/922920. Accessed on [2022-05-18].

|

| [11] |

Varma N R G, Babu T K, Ramprasad B, Ashwini D, Reddy T R, Sudhakar C, et al. Autonomous drones in agriculture: standard operating protocols for agrochemical application in field crops. Hyderabad: Professor Jayashankar Telangana State Agricultural University Press, 2022; Available: https://pjtsau.edu.in/files/notifications/2023/Circulars/sops-drone-pesticide-application-rice-pjtsau.pdf. Accessed on [2023-08-15].

|

| [12] |

Chanu T M, Ray D C. Comparative efficacy of different conventional pesticides against yellow stem borer under field condition on rice in Cachar district of Assam. Environment and Ecology, 2015; 33: 823–826.

|

| [13] |

IRRI, Title. Standard Evaluation System in Rice, 2014. Available: http://www.knowledgebank.irri.org/images/docs/rice-standard-evaluation-system.pdf. Accessed on [2022-06-08].

|

| [14] |

Rajeswaran J, Santharam G, Chandrasekaran S. Studies on compatibility and phytotoxicity of carbosulfan 25 EC with certain agrochemicals on cotton. Journal of Entomological Research, 2004; 28(3): 247–252.

|

| [15] |

Wang G B, Li X, Andaloro J, Chen P C, Song C C, Shan C F, et al. Deposition and biological efficacy of UAV-based low-volume application in rice fields. International Journal of Precision Agricultural Aviation, 2020; 3(2): 65–72.

|

| [16] |

Cox D, Gomez K A, Gomez A A. Statistical procedures for agricultural research. John New York: Wiley and Sons. 1984; 704p.

|

| [17] |

Sheoran O P, Tonk D S, Kaushik L S, Hasija R C, Pannu R S. Statistical software package for agricultural research workers. In Hooda D S (ed.). Recent Advances in information theory, Statistics & Computer Applications. Haryana: Hasija Department of Mathematics Statistics, Haryana Agricultural University. 1998; pp.139–143.

|

| [18] |

Wang C L, He X K, Liu Y, Song J, Zeng A. The small single-and multi-rotor unmanned aircraft vehicles chemical application techniques and control for rice fields in China. Aspects of Applied Biology. 2016; 132(3): 73–81.

|

| [19] |

Li J, Chen W T, Xu Y, Wu X M. Comparative effects of different types of tank-mixed adjuvants on the efficacy, absorption and translocation of cyhalofop-butyl in barnyard grass (Echinochloa crusgalli [L.] Beauv.). Weed Biology and Management, 2016; 16(1): 80–89.

|

| [20] |

Wang J, Lan Y B, Zhang H H, Zhang Y L, Wen S, Yao W X, et al. Drift and deposition of pesticide applied by UAV on pineapple plants under different meteorological conditions. Int J Agric & Biol Eng, 2018; 11(6): 5–12. doi: 10.25165/j.ijabe.20181106.4038

|

| [21] |

Chen S D, Lan Y B, Li J Y, Zhou Z Y, Liu A M, Mao Y D. Effect of wind field below unmanned helicopter on droplet deposition distribution of aerial spraying. Int J Agric & Biol Eng, 2017; 10(3): 67–77.

|

| Particulars | Parameter |

| Model | AGRICOPTER AG 365 with UIN UA00132S1EX |

| Service provider | Marut Dronetech Pvt. Ltd., Hyderabad |

| Dimensions | 1920 mm×1820 mm×500 mm |

| Pay load capacity/volume | 10 L |

| Endurance | 20 min |

| Power battery | 2 Nos. of |

| Number of nozzles | 4 Nos. |

| Nozzle type | XR 11002VP (Extended range-Flat fan) |

| Spray angle of the nozzle and tip | 110° |

| Spray pressure | 1.40-2.06 bars |

| Pump pressure | 1 MPa |

| Flight mode options | Manual/Semi-autonomous/Fully autonomous |

| Fail safe features | Return to home, hovering on signal lost |

| Spraying width | 3-5 m |

| Max. flying speed | 5.0 m/s |

| Max. flow velocity | 200-800 mL/min |

| Trt. No. | Treatment particulars | Spraying equipment |

| T1 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L | Drone |

| T2 | Tetraniliprole 200 SC @ 6.25 mL/L | Drone |

| T3 | Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L | Drone |

| T4 | Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | Drone |

| T5 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 25 mL/L | Drone |

| T6 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 5 g/L | Drone |

| T7 | Tetraniliprole 200 SC @ 6.25 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 25 mL/L | Drone |

| T8 | Tetraniliprole 200 SC @ 6.25 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 5 g/L | Drone |

| T9 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 2.66 mL/L | Taiwan sprayer |

| T10 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 0.53 g/L | Taiwan sprayer |

| T11 | Tetraniliprole 200 SC @ 0.6 mL/L+(Picoxystrobin 7.5%+Tricyclazole 22.5% SC) @ 2.66 mL/L | Taiwan sprayer |

| T12 | Tetraniliprole 200 SC @ 0.6 mL/L+(Tebuconazole 50%+Trifloxystrobin 25% WG) @ 0.53 g/L | Taiwan sprayer |

| T13 | Untreated Control | -- |

| Note: SC: Suspension Concentrate; WG: Wettable Granules. | ||

| Drone spray parameters | SOPs followed |

| Flight height | 2.5 m above the crop canopy |

| Flight speed | 3.6 m/s |

| Nozzle type | XR |

| Number of nozzles | 4 |

| Spray width | 3.5 m |

| Spray volume | 40 L/hm |

| Wind speed for drone fly | <5.0 m/s |

| Scale | Relative lesion height (RLH) |

| 0 | No infection observed |

| 1 | Lesions limited to lower 20% of the plant height |

| 3 | 20%-30% |

| 5 | 31%-45% |

| 7 | 46%-65% |

| 9 | More than 65% |

| Trt. No. |

Treatment details | YSB | WM/% | BS/% | SHB (PDI)/% | SHR/% | GD/% | Grain yield/ kg∙hm–2 |

|

| DH/% | WE/% | ||||||||

| T1 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L | 6.45ab(14.65)* | 6.85a(15.04) | 7.23ab(15.54) | 9.22c(17.47) | 51.85cd(46.04) | 18.44c(25.40) | 17.00c(26.49) | 5451hi |

| T2 | Tetraniliprole 200 SC @ 6.25 mL/L | 4.23a(11.83) | 5.94a(14.02) | 5.67a(13.70) | 7.19bc(15.52) | 48.52c(44.13) | 19.61c(26.23) | 18.00c(25.51) | 5614hi |

| T3 | Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L |

9.46d(17.69) | 15.21b(22.80) | 13.10d(21.20) | 3.09a(10.08) | 20.37ab(26.45) | 6.35ab(14.44) | 10.33ab(17.34) | 6024gh |

| T4 | Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L |

11.33d(19.64) | 17.09b(24.83) | 14.03d(21.92) | 2.62a(9.30) | 12.96a(20.60) | 4.44a(12.11) | 7.00a(14.04) | 6275gh |

| T5 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L |

8.36bc(16.78) | 8.97a(17.38) | 11.44bc(19.70) | 3.59a(10.91) | 12.96a(20.60) | 7.26ab(15.38) | 9.00b(18.71) | 6900de |

| T6 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L |

8.82bc(17.25) | 8.68a(17.10) | 10.38bc(18.71) | 3.28a(10.43) | 17.78ab(23.99) | 5.76ab(13.83) | 7.67ab(15.97) | 7726b |

| T7 | Tetraniliprole 200 SC @ 6.25 mL∙L–1+Picoxystrobin 7.5%+Tricyclazole 22.5% SC@ 25 mL/L |

6.90abc(15.20) | 7.69a(16.08) | 6.91ab(15.06) | 3.63a(10.97) | 25.93ab(30.56) | 7.38ab(15.66) | 9.33ab(17.68) | 7459bc |

| T8 | Tetraniliprole 200 SC @ 6.25 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L |

6.21abc(14.37) | 7.68a(16.06) | 7.08ab(15.35) | 3.44a(10.65) | 16.67ab(23.88) | 5.69ab(13.78) | 6.33a(14.04) | 7995a |

| T9 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L |

5.60ab(13.65) | 7.85a(16.15) | 8.98bc(17.42) | 3.70a(11.07) | 14.81a(22.34) | 8.41b(16.82) | 9.67ab(17.97) | 6729ef |

| T10 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L |

7.97ab(16.38) | 8.77a(17.21) | 8.49bc(16.91) | 3.21a(10.32) | 15.93a(23.36) | 5.79ab(13.90) | 8.33ab(16.07) | 7379bcd |

| T11 | Tetraniliprole 200 SC @ 0.6 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L | 7.90bc(16.12) | 7.00a(15.26) | 9.03bc(17.40) | 3.22a(10.31) | 20.37ab(26.77) | 6.84ab(14.99) | 10.67b(18.37) | 7155cde |

| T12 | Tetraniliprole 200 SC @ 0.6 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L |

6.96abc(15.25) | 5.86a(13.93) | 6.82ab(15.11) | 3.28a(10.42) | 18.52ab(25.42) | 5.08ab (12.97) | 9.00ab(17.07) | 8098a |

| T13 | Untreated control | 11.45d(19.76) | 18.07b(25.12) | 17.17e(24.45) | 10.93c(14.08) | 57.78d(49.45) | 27.16d(31.39) | 27.33d(31.49) | 4809j |

| Standard error (SE/m±) | 1.00 | 1.08 | 0.97 | 0.68 | 2.93 | 1.07 | 1.42 | 172.65 | |

| Critical difference CD (at 5% significance level) | 2.94 | 3.19 | 2.86 | 2.01 | 8.62 | 3.16 | 4.19 | 506.94 | |

| Coefficient of variation (CV/%) | 10.81 | 10.62 | 9.45 | 10.12 | 17.24 | 10.68 | 12.82 | 4.34 | |

| Note: YSB: Yellow stem borer; DH: Dead hearts; WE: White ears; WM: Whorl maggot; BS: Brown spot; SHB: Sheath blight; PDI: Percent disease index; SHR: Sheath rot; GD: Grain discoloration. *Figures in parentheses are angular transformed values. Numerical superscript letters represent Duncan’s multiple range test analysis. Figures in bold represent best-performing treatments. | |||||||||

| Trt. No. | Treatment details | Grain yield/ kg∙hm-2 | Incremental yield over control/ kg∙hm-2 | Incremental returns over control/ INR∙hm-2 | Incremental cost of cultivation/ INR∙hm-2 | ICBR |

| T1 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L | 5451 | 642 | 5475 | 1: 2.39 | |

| T2 | Tetraniliprole 200 SC @ 6.25 mL/L | 5614 | 805 | 6420 | 1: 2.56 | |

| T3 | Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L | 6024 | 1215 | 5520 | 1: 4.49 | |

| T4 | Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | 6375 | 1566 | 6120 | 1: 5.22 | |

| T5 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 25 mL/L | 6900 | 2091 | 9995 | 1: 4.27 | |

| T6 | Chlorantraniliprole 18.5% SC @ 3.75 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | 7726 | 2917 | 1: 5.62 | ||

| T7 | Tetraniliprole 200 SC @ 6.25 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC@ 25 mL/L | 7459 | 2650 | 1: 4.94 | ||

| T8 | Tetraniliprole 200 SC @ 6.25 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 5 g/L | 7995 | 3186 | 1: 5.63 | ||

| T9 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L | 6729 | 1920 | 9870 | 1: 3.97 | |

| T10 | Chlorantraniliprole 18.5% SC @ 0.4 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L | 7379 | 2570 | 1: 5.01 | ||

| T11 | Tetraniliprole 200 SC @ 0.6 mL/L+Picoxystrobin 7.5%+Tricyclazole 22.5% SC @ 2.66 mL/L | 7155 | 2346 | 1: 4.43 | ||

| T12 | Tetraniliprole 200 SC @ 0.6 mL/L+Tebuconazole 50%+Trifloxystrobin 25% WG @ 0.53 g/L | 8098 | 3289 | 1: 5.88 | ||

| T13 | Untreated Control | 4809 | 0.00 | 0.00 | 0.00 | 0.00 |

| Note: Market price of paddy=20,400 INR/t, Cost of Chlorantraniliprole 18.5% SC (60 mL)=2237.5 INR/hm2, Tetraniliprole 200 SC (100 mL)=2710 INR/hm2, Picoxystrobin 7.5%+Tricyclazole 22.5% SC (400 mL)=2260 INR/hm2, Tebuconazole 50%+Trifloxystrobin 25% (80 g)=2560 INR/hm2 Spraying cost (hm2); Taiwan sprayer spraying charges =INR.875/- & Drone spraying charges =INR.1000/-. | ||||||

| Particulars | Efficiency indices/% |

| Water saving by drone spray over Taiwan spray | 89.33% |

| Time saving by drone spray over Taiwan spray | 73.33% |

| Yield improvement by drone spray over Taiwan spray | 2.48%-4.36% |

| Field capacity • Drone spray • Taiwan spray | 8 hm2/d (20 acres/d) 2 hm2/d (5 acres/d) |

| Labor productivity • Drone spray • Taiwan spray | 4 hm2/d (10 acres/labor day) 1 hm2/d (2.5 acres/labor day) |